Welcome to the PSU AE Thesis Portofolio Site of Cherry Q. Lu | Construction Managment

TWIN RIVERS ELEMENTARY INTERMEDIATE SCHOOL | McKeesport | PA

|

| |

Building Statistics Part I. |

|

|

|

|

General Building Information |

|

Name: Twin Rivers Elementary/Intermediate School Also known as: New Cornell Elementary/Intermediate School

|

|

Location: 1600 Cornell St, McKeesport, PA 15132

ccupancy: Educational

Owner: McKeesport Area School District

Size: 127,000 square feet

Stories Above Grade/Total Levels: 3 stories

Dates of Construction: February 2013-January 2014

Building Cost: Approximately $28 million overall project cost

Project Delivery Method: Design-Bid-Build |

|

|

|

|

|

Information about the CPEP

The Capstone Project Electronic Portfolio (CPEP) is a web‐based project and information center. It contains material produced for a year‐long Senior Thesis class. Its purpose, in addition to providing central storage of individual assignments, is to foster communication and collaboration between

student, faculty consultant, course instructors, and industry consultants. This website is dedicated to the research and analysis conducted via guidelines provided by the Department of Architectural

Engineering.

For an explanation of this capstone design course and its requirements please click here. |

| |

Project Team |

| Owner: Mckeesport Area School District |

| Architect: J C Pierce Project Manager: Pete Szymanski |

| Construction Manager: PJ Dick Project Executive: John Taormina |

General Contractor: Gurtner Construction Superintendent: Ryan Mangan |

Civil Engineers: Phillips & Associates, Inc. |

| Structural & MEP Engineers: Loftus Engineers |

| Environmental Engineers: American Geosciences, Inc. |

| |

Architecture |

| Architecture of Twin Rivers Elementary/Intermediate School |

The project is located along the west side of the 1600 block of Cornell Street, in McKeesport, PA. The owner of the project is the McKeesport Area School District. The school is built to replace the former Cornell Elementary School. The construction of this project is part of the plan to consolidate district’s five elementary facilities into three. The school district believes the Twin Rivers Elementary/Intermediate School is of an innovative design that will thrust the old steel town of McKeesport into the future. The new school will accommodate approximately 750 students and will serve as the Mathematics and Science Academy for the McKeesport Area School District.

The goal for the Twin Rivers Elementary/Intermediate School is to achieve a LEED Gold Certification. LEED features of this project include a robust thermal envelop, high-performance mechanical systems, energy conserving electrical system, extensive day-lighting along with exterior views, a rain water collection/reuse system and a potential for a wind-turbine supplemental energy system.

Another architecture feature is that: two small vertical wind turbines will be installed atop steel masts anchored to the face of the exterior building wall at the ends of the two classroom wings, along the rear / east side of the site. The wind turbines will primarily serve as an educational tool and generate enough electricity to provide minimal assistance in powering the facility. |

| |

| Applicable Codes |

ICC (IFC): ICC International Fire Code, 2006

NFPA 101 - Life Safety Code, 2006.

ICC (IBC) - ICC International Building Code, 2006.

ICC (IPC) - ICC International Plumbing Code, 2006.

ICC (IMC) - ICC International Mechanical Code, 2006.

IAPMO (UPC) - IAPMO Uniform Mechanical Code, 2006.

ICC (IFGC) - ICC International Fuel Gas Code, 2006.

ICC (IPSDC) - ICC International Private Sewage Disposal Code, 2006.

NFPA 70 - National Electrical Code, 2008.

ICC (IEC) - ICC International Electrical Code, 2006.

ICC (IECC) - ICC International Energy Conservation Code, 2006.

ICC (IPMC) - ICC International Property Maintenance Code, 2006. |

| |

Zoning Information |

Zoning Code: McKeesport.

Since the Twin Rivers School is to replace Corrnel Middle School in the same site, there were no major zoning complications. |

| |

| Historical Requirements |

| This building was not placed on a Historical site. It was previously Cornell Elementary for the same school district. |

| |

Building Enclosure |

| Building Façade |

Exterior wall construction will be perimeter structural steel framing. Typical Exterior Walls will be approximately 14-1/8” thick resulting in an estimated system value of R21.Typical Exterior walls will be a metal stud cavity wall construction. The walls will be an approximately 14-1/2” total thickness for an estimated system value of R20.

Typical exterior finishes will include modular brick veneer beginning at grade and extending up to a height as indicated on the exterior elevations, capped by a ground face CMU sill. Cellular weeps 24” O.C. and continuous corrugated weeps will be used at all through wall locations.

Through wall flashing will be copper laminate fabric with a stainless steel drip edge.

Above the CMU sill will be a horizontal prefinished metal siding extending to the underside of either a prefinished metal soffit or prefinished metal coping, as determined by the roof condition.

The final thickness of the exterior wall insulation will depend on the completed energy model and the requirements of the mandatory LEED for Schools ‘Optimize Energy’.

Exterior walls below grade will be insulated with 2” polystyrene board from floor level to below the frost line (typically 3’-4’).Exterior classroom windows will be thermally broken aluminum frames with a clear anodized finish. The lower window pane will be an operable awning pane and the upper panes will be stationary fixed panes. Internal screens with continuous hinges will be included for all operable window units. Glazing will be low-E insulated triple glazed system with integral window blinds.

Exterior aluminum storefront and curtain wall glazing systems will be manufacturer’s standard clear anodized finish. Glazing will be low-E clear 1” insulated units. All glazing at entrances will be tempered safety glass and all interior glazing in fire rated openings will be ceramic fire glass.The exterior closure walls of the classroom wings will be framed with 8” deep light gage metal, 18 gage, light gage metal

studs and 16” on center. The perimeter closure walls of the gymnasium will be 12” block with reinforcing bars spaced

either 16” on center or 32” on center. |

| |

| Roofing System |

| Flat roofs will be sloped at ¼” per foot minimum, light in color, and will be either a two-ply SBS modified bitumen roofing system or a three-ply modified system. Roof insulation will be a combination of extruded polystyrene with polyisocyanurate insulation to achieve positive slopes / crickets to roof drains, as required to achieve a minimum value of R-30; the final thickness of the roof insulation will depend on the completed energy model and the requirements of the mandatory LEED for Schools ‘Optimize Energy’.

Metal roofs will be standing seam. Rigid roof insulation will be in thickness as required to achieve a minimum value of R-30.At the flat roof areas the roof framing will be comprised of structural steel columns and beams in-filled with open-web

steel joists spaced 4’-0” to 5’-0” on center and a 1-1/2” deep, wide-ribbed, galvanized metal roof deck. Mechanical roof

top units will be located on the flat roof areas and supported directly on the open-web roof joists. At the classroom wings

rigid bents will be used to frame the sloped roofs over the classrooms. At the classroom wing corridors light gage metal

or metal-plated wood trusses spaced 2’-0” on center will be used to frame the high corridor roofs. |

| |

Sustainability Features |

This project will achieve a minimum of LEED Silver Certificate and has a goal of achieving Gold Certificate by USGBC. As a team, JC Pierce and National Geosciences worked to get the project up to LEED standards. A mix of geothermal central loop system and hot water boiler will be utilized. The building will have a featuring glass-framed mechanical room that includes portions of the geothermal heating and cooling system for both function and educational experience. The building will also include a grey water capture system for sustainability reason. This system will not only help this project achieve LEED points in the short-run but also help the school to lower the utility cost for the long-run. Curtain wall system will be utilized to maximize the day-lighting. In the meantime, several ways of solar shading will be implemented. Louvers are to be placed above southern windows. Portions of the large curtain wall in the courtyard are to have metal mesh coverings to maintain desired solar gain. Two educational vertical wind turbines will be installed along east side of the building. However, the wind turbines will primarily serve as an educational tool and generate enough electricity to provide minimal assistance in powering the facility. |

| |

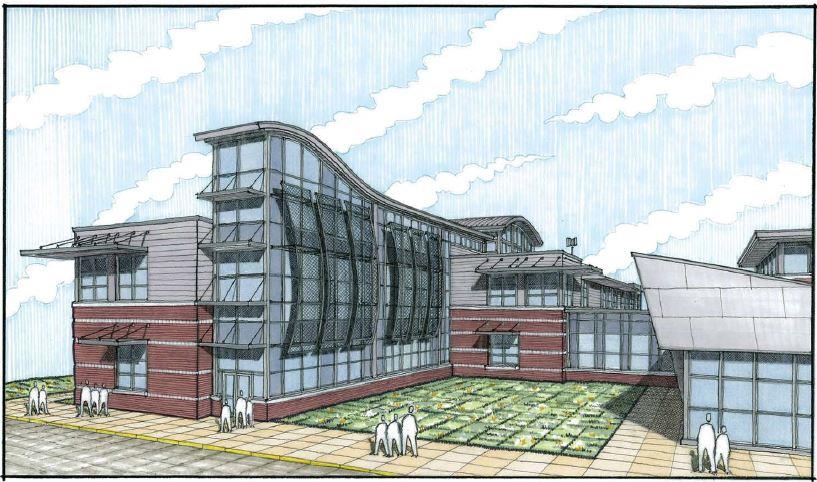

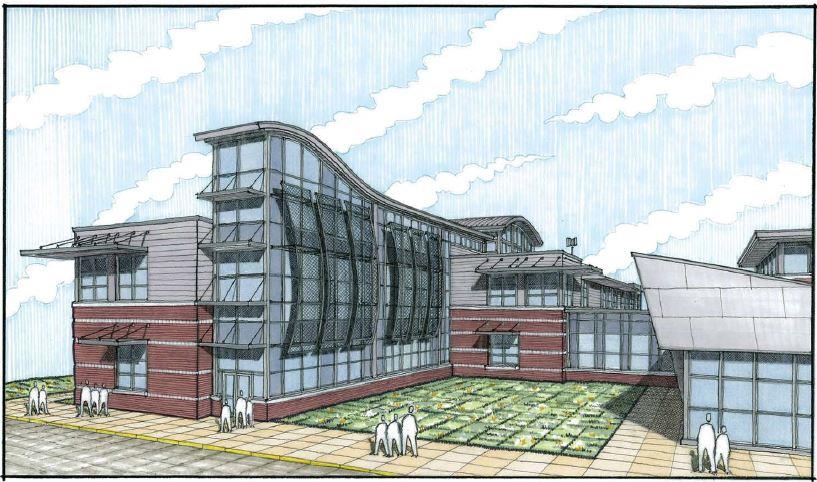

Renderings |

|

| Rendering of curtain wall system with metal meshes. |

| |

Building Statistics Part II. |

CONSTRUCTION

The project is located along the west side of the 1600 block of Cornell Street, in McKeesport, PA. The owner of the project is the McKeesport Area School District. The school is built to replace the former Cornell Elementary School. The construction of this project is part of the plan to consolidate district’s five elementary facilities into three. The project is a design-bid-build project and the school district awarded contracts to JC Pierce and Gurtner for the construction. The new school will accommodate approximately 750 students and will serve as the Mathematics and Science Academy for the McKeesport Area School District.

The goal for the Twin Rivers Elementary/Intermediate School is to achieve a LEED Gold Certification. LEED features of this project include a robust thermal envelop, high-performance mechanical systems, energy conserving electrical system, extensive day-lighting along with exterior views, a rain water collection/reuse system and a potential for a wind-turbine supplemental energy system.

STRUCTURAL SYSTEMS DESCRIPTION

Foundations

Foundation system will be shallow spread footings down to the frost line. Ground level slabs will be 4” deep concrete slabs-on-grade.

Floor Framing

At the 2nd Floor the framing system will be structural steel columns and beams in-filled with open-web steel joists spaced 2’-0” on center and a 3” concrete slab with ½” form deck.

Roof Framing

At the flat roof areas the roof framing will be comprised of structural steel columns and beams in-filled with open-web steel joists spaced 4’-0” to 5’-0” on center and a 1-1/2” deep, wide-ribbed, galvanized metal roof deck. Mechanical rooftop units will be located on the flat roof areas and supported directly on the open-web roof joists. At the classroom wings rigid bents will be used to frame the sloped roofs over the classrooms. At the classroom wing corridors light gage metal or metal-plated wood trusses spaced 2’-0” on center will be used to frame the high corridor roofs.

Exterior Walls

The exterior closure walls of the classroom wings will be framed with 8” deep light gage metal, 18 gage, light gage metal studs and 16” on center. The perimeter closure walls of the gymnasium will be 12” block with reinforcing bars spaced either 16” on center or 32” on center.

ELECTRICAL SYSTEMS DESCRIPTION

Power Source & Metering

Voltage: 208/120V, 3-Phase, 4 wire

Capacity: As required (approximately 10 watts per square foot)

Primary Power Distribution

The primary distribution system will be 208/120V, 3-Phase, 4 wire. A 480 volt distribution system will be reviewed for cost effectiveness. The 480/277V system will likely not be a cost saving approach for the size of building under consideration.

Secondary Power Distribution

The secondary distribution system will be 208/120V, 3-Phase, 4 wire.

Emergency/Standby Power

A Diesel Generator set is recommended since this ensures that a source of power is always available independent of utility sources.

Power for Mechanical/Plumbing Loads

Power for loads over 2 HP will be 208V, 3-Phase. Loads between ½ HP and 2 HP will be 208V, 1-Phase, loads less than ½ HP will be 120V. Mechanical will provide starters/VFD’s/control panels for mechanical equipment. Electrical will add local disconnect switches or motor protector switches where not provided by mechanical.

PLUMBING SYSTEMS DESCRIPTION

Plumbing System

• The sanitary, soil, waste, and vent systems shall be PVC plastic pipe, except in return air plenums where they shall be cast iron.

• The storm water system above ground shall be standard weight cast iron pipe. All underground storm water piping shall be PVC plastic pipe.

• The domestic hot and cold water piping shall be type “L” copper tubing.

• The plumbing fixtures shall be vitreous china with polished chrome accessories. The water closets shall be wall mount with sensor operated dual-flush flush valves (1.6 gallons per flush for solid waste, 1.1 gallons per flush for liquid waste).

• The urinals shall be wall hung low-flow 1/8 gallon per flush.

• The lavatories shall have sensor operated faucets that provide tempered water at 0.5 gpm.

• Water heaters shall be 96% efficient, gas-fired.

• Rainwater from the school roof will be collected in cisterns, filtered, and recycled for use in the toilets. A transfer pump will pressurize the supply line to the toilets.

MECHANICAL SYSTEMS DESCRIPTION

General

The overall design will be based on achieving a 30% energy savings compared to a baseline HVAC design per ASHRAE 90.1-2007. ASHRAE’s Advanced Energy Design Guide for K-12 School Buildings will be used as a guideline for design. This will assist in earning points toward the desired LEED Gold rating.

Geothermal System

The HVAC system will utilize a vertical, closed loop, earth coupled water loop connected to water-to-air heat pumps providing heating and cooling for building spaces. Individual heat pumps will be provided for perimeter and interior classroom zones. Units will be concealed either in the return air plenum above the ceiling or closets for sound attenuation. Each unit will be provided with an individual room sensor. The ground source heat pumps will be two stage horizontal extended range units equipped with variable speed fans. A solenoid valve at each heat pump shall stop tempered water flow when the compressor is off. Heat pumps shall utilize HFC 410A refrigerant (Non CFC type.)

Ventilation Air System

Ventilation air will provide by a Dedicated Outdoor Air System (DOAS) which will be ducted to spaces throughout the building. The DOAS unit shall be roof mounted, dual-stage, water-to-air, total enthalpy heat exchanger with outside air supply and exhaust fans, supply air filters, motorized desiccant heat wheels with pre-purge, heat wheel bypass dampers, DX cooling coil, and VFD motor controllers on supply and exhaust fans. The DOAS unit shall be prewired, single point electrical connection, with unit mounted disconnect switch. Minimum thermal effectiveness of the enthalpy wheel shall be 75%. The air handler section shall be constructed of 2” thick insulated double wall panels with solid liner. Building exhaust air shall be ducted to the DOAS unit for air-to-air energy recovery. Toilets and janitor closet shall be supplied with transfer air and exhausted by the DOAS unit.

Exhaust Air Systems/DOAS Locations

Exhaust room ventilation air and exhaust air from the toilets will be exhausted through the DOAS and using a total heat recovery enthalpy wheel to pre-condition the outdoor air for the DOAS unit. There will be several DOAS systems that will be distributed across the building to reduce duct runs. In general each class room wing will have one or two units each, the administration area will have one DOAS unit and the cafeteria, library and gym will be each served by dedicated heat pump, roof-top unit with heat recovery wheels that will introduce outside air through the units and will not need a DOAS unit.

HVAC Distribution Systems

Supply air diffusers will generally be 24x24 architectural plaque type for overhead air distribution throughout. Return grilles will be lay-in louvered type for plenum or ducted return. Where transfer air is required, lined transfer elbows will be used across walls to structure. High filtration MERV 13 rated air filters will be provided in the return air ductwork for each fan coil unit and heat pump. Ductwork shall be constructed and installed in accordance with SMACNA HVAC Duct Construction Standards. Ductwork shall be rated and sealed for 2” static pressure. Fire dampers shall be provided at all penetrations of floors and fire-rated walls in ductwork and return air openings. In general, the return space above the ceiling will be used as a plenum. All new supply ductwork will be insulated with 2” thick fiberglass blanket insulation. |

|

|

|

|

Contact Cherry Qianhui Lu |

This page was last updated on 10/23/13 by Cherry Q. Lu and is hoted by the AE Department© 2014. |

|

|